SMS Solutions For:

AS9100D was released September 20, 2016. This version includes requirements for configuration management, risk management, special requirements, critical items, on-time delivery, project management, supplier scope of approval and others.

OmniSMS is your solution for successful AS9101D process-focused and performance-based audits.

Part 5 / NAS9927 SMS Standards Meet AS9100D

14CFR Part 5 and NAS 9927

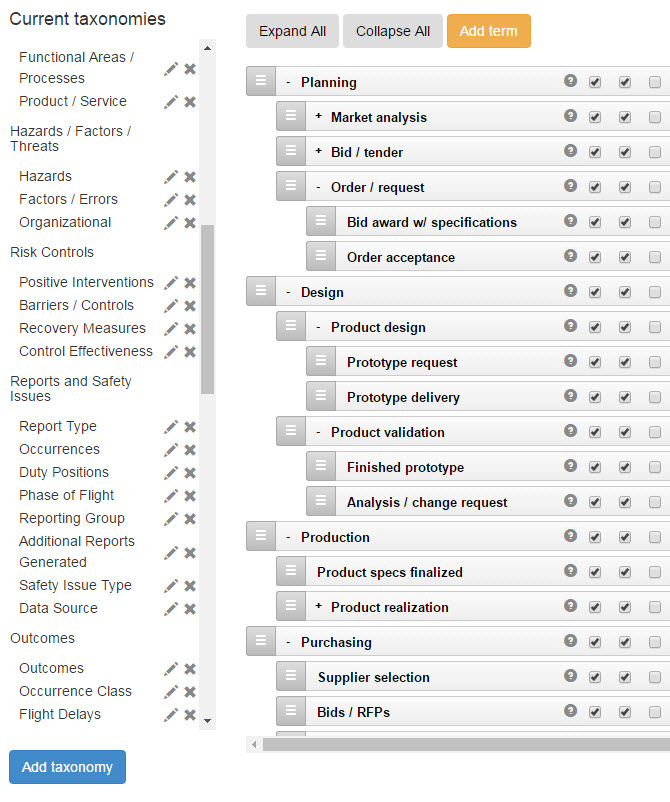

OmniSMS is designed to meet both 14 CFR Part 5 requirements for SMS as well as National Aerospace Standard (NAS) 9927: Safety Management Systems and Practices for Design and Manufacturing. D&M organizations can now save many hundreds of hours of development time meeting these complex requirements. OmniSMS templates let you complete your Declaration of Compliance in just a few hours and your SMS Implementation Plan in less than a day. But the benefits don’t stop there. OmniSMS includes safety / quality policy and code of ethics templates ready for you to edit. The web-based system supports quantitative airworthiness risk assessments, as well as qualitative assessments in other risk dimensions. Easily configure functional areas to align with your organizational structure and the processes you already have in place. Create custom groups for email notifications, safety comms, memos and more. It’s all configurable in OmniSMS.

Measure Process Performance

High and low-level key performance indicators (KPIs) can easily be created for both safety and quality measurements, together with objectives for improvement. Examples: Set low-level QKPIs for nonconformities within a process across one or more departments; or in a department for one or more processes. Set high-level QKPIs for major or critical nonconformities, and drill down to see the departments and/or processes in which they have occurred. When a nonconformity report or audit finding is received, KPIs automatically update. If an alert threshold is exceeded, responsible managers in user-defined notification groups receive an alert email for prompt corrective action.

Customer Focus / COS

Manage continued operational safety (COS) using a configurable COS Report. Data collection is configurable to include P/N, S/N, ATA code, applicability, etc. with subsequent investigation identifying causal factors and possible process deficiencies. Preventive and corrective actions are then applied to address the root causes of in-service failures.

OmniSMS lets customers provide feedback directly into the system without the need to login. The Customer Feedback report provides a simple interface for customers to report nonconformities or other safety / quality concerns, and lets them attach any number of documents or images to the report submission. Analytics help you identify and evaluate customer satisfaction, process performance, and product conformity for continuous improvement.

SMS / QMS Risk Assessment and Workflow

OmniSMS uses two aligned risk assessment methods: reactive Event Risk classification (ER) and proactive Risk Assessment (RA). They use the same workflow, but provide a critical distinction:

- For events that occur (e.g., minor injuries, damage events) ER identifies and analyzes the effectiveness of controls that prevented the event from becoming a serious incident or accident;

- For nonconformities, identified hazards / threats and management of change, proactive RA permits risk assessments in various dimensions of Airworthiness, People, Assets, Compliance, Reputation, and Environment.

After risk analysis, OmniSMS’ user-friendly workflow continues with branched investigations, identification of contributing and causal factors (root causes), recommendations for improvement, preventive / corrective actions, CAP acceptance, monitoring, and follow-up. Tasks display on users’ calendars, and auto-email alerts assure nothing is overlooked.

Contact Omni Air Group today for more information.